SNOWY TTi

SNOWY 5 - 7 - 12 TTi

SNOWY 16 TTi

SNOWY 18 - 27 TTi (Big Size)

PRODUCTS

| Model | Per cycle (kg) Mix added min – max |

Per cycle (l) Gelato produced min – max |

Per hour (kg) Gelato produced min – max |

Per hour (l) Gelato produced min – max |

Granita per cycle (kg) min – max |

|---|---|---|---|---|---|

| Snowy 5 TTi 220V | 1.5 – 5 | 2 – 7 | 9 – 30 | 12 – 42 | 2 – 5 |

| Snowy 5 TTi | 1.5 – 5.5 | 2 – 8 | 9 – 33 | 12 – 45 | 2 – 6 |

| Snowy 7 TTi | 1.5 – 7.5 | 2 – 10.5 | 9 – 45 | 12 – 60 | 3 – 8 |

| Snowy 12 TTi | 2 – 12.5 | 3 – 17 | 12 – 75 | 18 – 100 | 4 – 13 |

| Snowy 16 TTi | 3 – 15.5 | 4 – 21 | 18 – 90 | 24 – 130 | 6 – 16 |

| Snowy 18 TTi | 3 – 18 | 4 – 25 | 18 – 110 | 24 – 150 | 7 . 18 |

| Snowy 27 TTi | 4 – 27 | 6 – 38 | 24 – 160 | 36 – 220 | 10 – 27 |

NOTE

Capacities can change according to the ingredients used, temperature or product consistency at the end of the batch freezing process.

All specifications mentioned must be considered approximate.

Valmar reserves the right to modify, without notice, all parts deemed necessary.

CHARACTERISTICS

Valmar’s Snowy TTi batch freezers are a new technological score achieved in the field of artisan gelato. Traditional product programmes and work step selection tools have been replaced by a new touch & type PLC. The innovative VALMAR Combisystem quality standards the gelato produced is now more resistant to melting as overrun is up to 40% of mix weight. The innovative VALMAR Combisystem has deeply changed quality standards and the gelato produced is now more resistant to melting as overrun is up to 40% of mix weight. Air incorporation in marketable maintains it more creamy and soft. Gelato output process is one of the leading technological innovations. The stirrer rotation speed varies automatically and progressively thus simplifying topping procedures as well as the adding of extra ingredients.

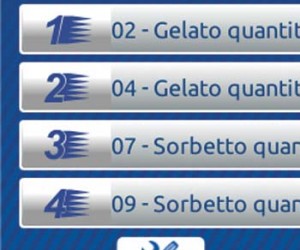

SOFTWARE AND PLC

The software is an integrated digital and analog system designed to automatically manage all the programmes by means of a PLC.

TOUCH & TYPE

The user can choose to operate the machine in Touch mode or in the traditional Type mode. The 4.3” LCD touchscreen has clear and intuitive icons that enable to manage and monitor each operating phase.

BATCH FREEZING AND PRODUCT OUTPUT INVERTER

Stirrer rotation inverter, range from 7 up to 70 Hertz. With the new Snowy TTi a perfect batch freezing depending on produced quantities, on mix features and on ingredients and their mix formulation is now readily available thanks to PLC and inverter. Totally new is the possibility to select the automatic speed adjustment mode of outgoing gelato, which does not melt during the whole outgoing process.

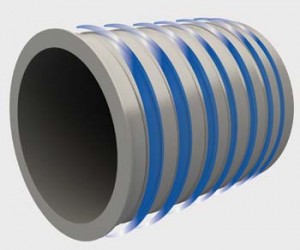

CYLINDER DESIGN

The cylinder is designed and tested to ensure a perfect combination in terms of chilling performance, freezing and micro-crystallization speed as well as optimized air incorporation.

STIRRER®

Special design helicoidal stirrer with blade variable convergence and high-performance scrapers: these are only some of the features marking out the new TTi series stirrer. A perfect batch freezing is the result of a systematic and uniform spreading of gelato on the whole cylinder surface thus avoiding the excessive freezing of gelato on the blades or in the middle of the cylinder.

SCRAPERS®

The scraping effect on the cylinder surface resulting in a extremely high heat rate efficiency as well as a high energy saving is given by the strength of the materials the scrapers are made of, their special inclination on the touch point and the specific high-thrust spring. The material scrapers are made of is provided with EC marking for use in food handling equipment.

DIRECT EXPANSION SYSTEM

Refrigerant gas direct expansion system on the batch freezing hollowed spiral cylinder having a progressively variable diameter to optimize the chilling performance on the whole cylinder surface.

CHECK OF GELATO CONSISTENCY

The check of gelato consistency is performed through stirrer torque measurement in Nm, gas temperature measurement as well as measurement of gelato inside the cylinder. Thanks to this technological innovation the desired gelato texture is obtained regardless of any recipe.