MULTY P TTi

MULTY P 7 TTi

MULTY P 12 TTi

PRODUCTS

| Model | Per cycle (kg) Mix added min – max |

Per cycle (l) Gelato produced min – max |

Per hour (kg) Gelato produced min – max |

Per hour (l) Gelato produced min – max |

Granita per cycle (kg) min – max |

Custards per cycle (kg) min – max |

|---|---|---|---|---|---|---|

| Multy P 7 TTi | 1.5 – 7.5 | 2 – 10.5 | 9 – 45 | 12 – 60 | 2 – 7 | 3 – 10 |

| Multy P 12 TTi | 2 – 12.5 | 3 – 17 | 12 – 75 | 18 – 100 | 3 – 10 | 5 – 14 |

NOTE

Capacities can change according to the ingredients used, temperature or product consistency at the end of the batch freezing process.

All specifications mentioned must be considered approximate.

Valmar reserves the right to modify, without notice, all parts deemed necessary.

CHARACTERISTICS

The innovative series Multy P TTi is born from Valmar’s experience: multiporpuse combined units able to meet the most advanced and complex requirements of the food sector.

Thanks to Multy P TTi the operator does not have to modify his recipes to operating procedures any more, on the contrary it is the machine itself that adapts to any professional requirements to achieve top-level quality standards.

Multy P TTi is a single-unit machine made up of two independently and separately operating tanks. The upper one heats and cooks up to 125°C while the lower one cools and freezes.

MULTY P TTi UNEQUALLED COOKING

TANK

It is a real “technological pot” with a very large bottom surface area thanks to the ratio between diameter and depth. Thermal exchange optimization without burning or sticking any product inside. The stirrer is provided with a patented counter-stirrer, easily and completely dismountable. Uniform scraping system on the whole cylinder surface, easy to remove and wash.

COOKING

Fast performances, high temperature precision, thermal inertia reduction even in case of dense products are some of the machine peculiarities. All this can be obtained as the machine is provided with what follows:

– double and triple resistance heating devices (for Multy P 12 TTi) electronically governed by PLC. Resistance heating devices can operate individually, alternatively or simultaneously;

– three probes to check temperature precision and reduce thermal inertia;

– uniform heating from 20% to 100% of tank maximum capacity;

– cooking temperature up to 125°C.

INVERTER FOR HEATING AND COOKING

Upper tank stirrer provided with a 5 to 70 Hertz independent inverter (speed variator) to heat and cook high-density products with reduced thermal exchange.

LID

Double lid with opening system actuated by servo-assisted hydraulic pistons for easy ingredient introduction even in case of product in progress. The machine has not to be stopped in full compliance with certified EC safety regulations.

TAP®

External way wide-diameter tap, working diameter 4 cm for the direct outgoing of products to the cooling cylinder, even the more dense ones, max 15 seconds for 7 kg of high density product.

– Easy and fast to dismount. Appropriate sanitation of any surface in contact with the product.

– EC certified accident prevention and safety measures.

– Completely in 18/10 stainless steel. Long-life and easy sanitation in dishwasher without deterioration.

– Rotation up to 180° to operate the heating tank also independently from the cooling cylinder.

– Servo-assisted gradual opening system: no jerky movement, no squirt.

VERSATILITY

Heating and/or cooking procedures with product outgoing directly from the heating cylinder independently from the batch freezing cylinder.

Anti-squirt system during pouring and batch freezer operation with a liquid mix.

Shelf space for hot product output independent from the cooling cylinder.

MULTY P TTi COOLING AND BATCH FREEZING

VALMAR COMBYSISTEM®

The new system has deeply changed artisan batch freezing quality standards. The produced gelato is now creamy and more resistant to melting as overrun is up to 40% of mix weight. Air incorporation in marketable gelato keeps it more creamy and soft.

GELATO OUTPUT

Totally new is the output process governed by the stirrer speed rotation automatic adjustment. Speed varies automatically and progressively and prevents gelato from easily melting during the whole outgoing process. Speed progression is customizable. This is a very practical solution in case of variegated gelato production.

INVERTER

Stirrer rotation inverter, range from 5 up to 70 Hertz. Many different products are now readily available thanks to PLC and inverter as well as to a perfect batch freezing which depends on produced quantities, mix features, ingredients and their mix formulation. Totally new is the possibility to select the automatic speed adjustment mode of the outgoing gelato, which does not melt during the whole outgoing process.

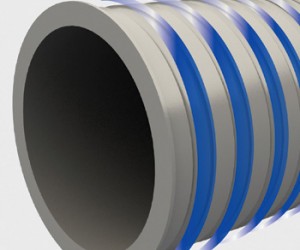

CYLINDER DESIGN

The cylinder is designed and tested to ensure a perfect combination in terms of chilling performance, freezing and micro-crystallization speed as well as optimized air incorporation.

STIRRER®

Special design helicoidal stirrer with blade variable convergence and high-performance scrapers: these are only some of the features marking out the new stirrer. A perfect batch freezing is the result of a systematic and uniform spreading of gelato on the whole cylinder surface thus avoiding the excessive freezing of gelato on the blades or in the middle of the cylinder.

DIRECT EXPANSION SYSTEM

Refrigerant gas direct expansion system on the batch freezing hollowed spiral cylinder having a progressively variable diameter to optimize the chilling performance on the whole cylinder surface.

CHECK OF GELATO CONSISTENCY

The check of gelato consistency is performed through stirrer torque measurement in Nm, gas temperature measurement as well as measurement of gelato inside the cylinder. Thanks to this technological innovation the desired gelato texture is obtained regardless of any recipe.